Testing of smart meters includes various tests and means of analysis. These include functional tests of common daily procedures. Functional tests can also be used for testing the data communication of the meter. However, the reason that the results of this type of testing only reveal half the truth is explained in this article.

Functional testing

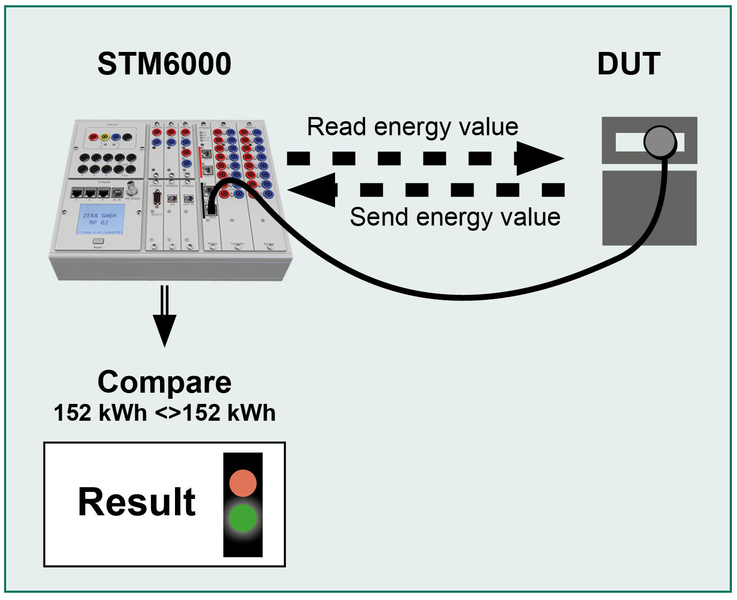

The objective of a functional test is to ensure the proper execution of a functional procedure. For example, a predefined value is queried, the corresponding response is compared with the expected value and this is subsequently evaluated (correct or incorrect). If the returned value and the expected value diverge, the result is then “Failed”. If the result is negative, the meter can be sorted out. Meters that are found to be “good” can be deployed in customer installations.

Functional tests that have delivered positive results in the laboratory, however, only provide information about whether the meter under test will later be able to communicate properly in the field with other pieces of equipment. The reason is that a functional test evaluates the result, but not the manner in which the communication operates between the test system and the meter under test.

Consequently, meters under test are not evaluated based on their communication behaviour, but instead on the result they return.

So how can you ensure that meters under test, perhaps even from different manufacturers, can communicate with each other properly based on a common specification?

Communication analysis

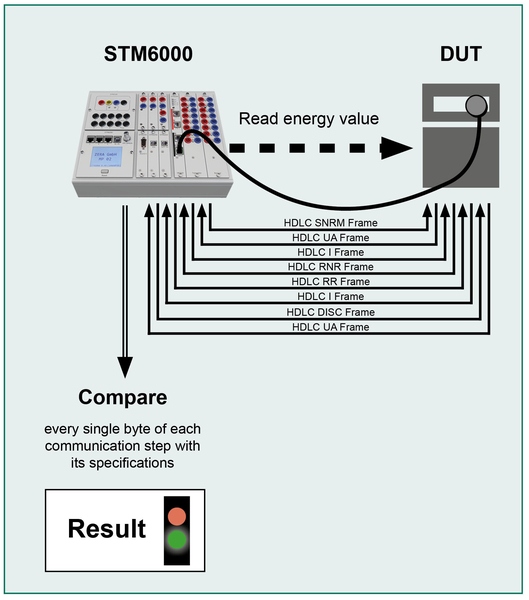

The objective of communication analysis is to investigate the communication of the meter under test in detail and to ensure that each byte transmitted complies with the specifications. In contrast to a functional test, the focus of this test is not an evaluation of the content transmitted, but rather compliance with the communication procedure used in the system.

In the communication analysis, a test is considered to have been “passed” when each individual byte of the communication protocol has been transmitted in compliance with the specification.

A meter under test would then be considered to have “failed” if a detail in the transmission was not specification compliant (sequence, protocol-specific contents, timing, etc.). Such a test can be applied for the meter communication which ist specified with sufficient clarity. The payload (useful information) to be transmitted is not the focus of a communication analysis.

Our figure shows a schematic representation of a communication analysis with a focus on the HDLC protocol and the telegrams associated with this. In addition to the query of the meter reading and the response of the meter in the i-frame, six additional communication frames are exchanged. To ensure error-free communication between two devices, every component of these frames must be implemented in compliance with the specification.

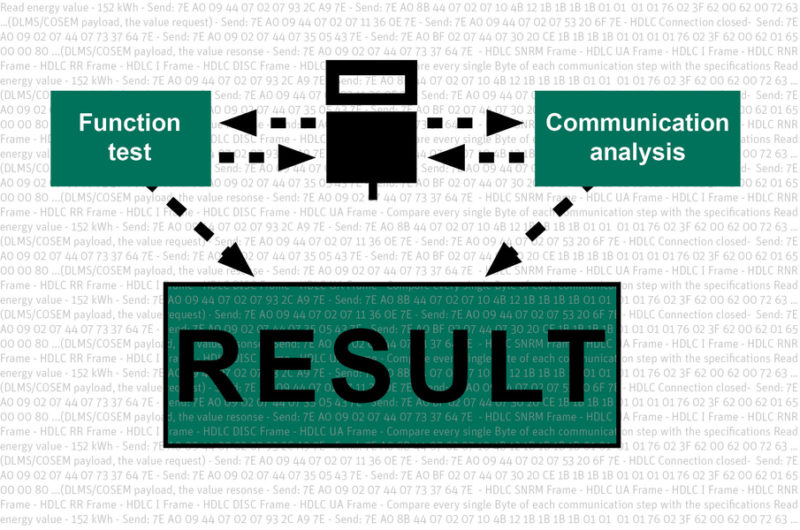

Functional testing vs. communication analysis

The objectives of a functional test and a communication analysis differ in content. In one, the focus is on the quality of a function. In the other, the focus is on a detailed examination of the communication process that goes beyond the mere fulfillment of a function. Only the combination of both types of test provide comprehensive insights into the data communication of the meter under test and enable the testing agency and the meter manufacturer to determine measures on their own.

Communication analysis makes it possible to draw conclusions concerning at what point a communication process is faulty. The analysis could make it clear, for example, that timing requirements in the communication process are not in compliance with the specification. For example, the specification for the meter under test could be: Send response data within 10 ms after sending the request. If the meter only sends the data after 50 ms, this is considered to be “not compliant with specification” and represents a faulty behaviour.

Detecting weaknesses of this nature already during sampling saves you enormous costs as a meter manufacturer or utility company.

A communication analysis requires no separate test cases or procedures, but can simply run in the background of a functional test. When a functional test is evaluated as being positive, a communication analysis can still reveal errors. This provides you with all the necessary evaluations of the results which enable a comprehensive statement to be made concerning the quality

Conclusions

A functional test is important, but it does not allow conclusions to be drawn as to why a meter under test is faulty. When complemented by a communication analysis, which compares all of the protocol-specific parameters and indicators with the specification, you obtain a comprehensive result concerning the quality of your meter under test. The communication analysis can run in parallel to the metrological testing with its communication steps and, as needed, indicate the non-conformances in detail. It can also be used in addition to the functional test. In the best case, the communication analysis of the device under test is carried out in the background for each test.

With our STM6000 digital measuring system, you have the opportunity to examine your meter in detail, including the aspect of data communication. This type of analysis for identifying deviations becomes indispensable at the latest when a key role is played by interoperability – meaning the communication of several devices with each other, possibly from different manufacturers and using the same standard.

Would you like some advice on smart meter testing? Please contact us. Email sales@zera.de